The COVID-19 pandemic has highlighted the importance of contact safe surfaces to minimise the transmission of bacteria and viruses from unclean surfaces. The challenge of keeping surfaces clean is faced every day in environments such as food factories, hospitals and public transport.

There are numerous articles and research papers highlighting the antimicrobial benefits of materials such as copper. However, high concentrations of copper are expensive, prone to tarnishing, and have reduced mechanical properties and corrosion resistance when compared to commonly used stainless steel.

The challenge was to develop and validate materials with antimicrobial properties, that are cost effective and have appropriate structural integrity and corrosion resistance for demanding applications.

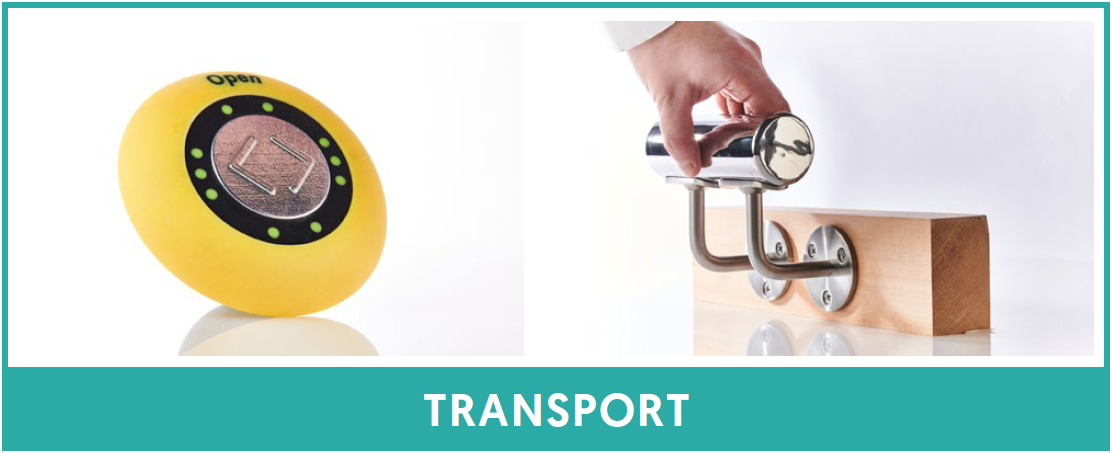

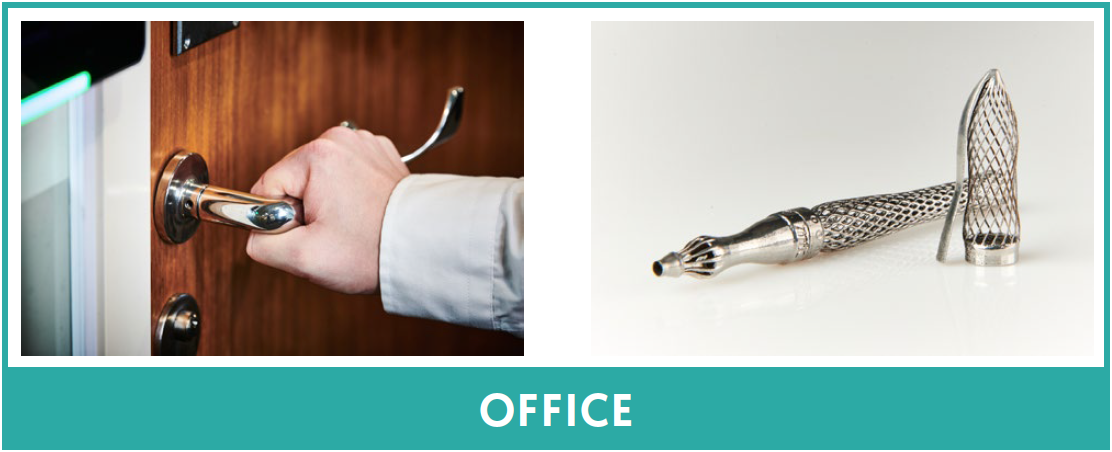

The Advanced Materials Processing team used MTC’s industry network, such as food manufacturer Samworth Brothers, to identify applications for contact safe surfaces. With support from the National Centre for Additive Manufacturing (NCAM), the team designed and manufactured application relevant demonstrators using commercially available copper-containing stainless steel. Additive manufacturing provided the freedom to manufacture a range of part designs from a powder feedstock source. A thermal process and an ultra-low temperature cooling process were applied to uniformly distribute fine copper particles within the solid stainless steel surface.

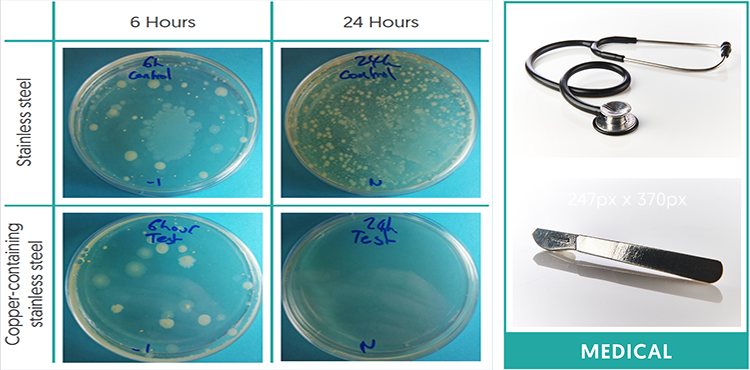

To demonstrate the antimicrobial nature of the material, the MTC collaborated with Campden BRI, a research centre specialising in the food industry. Metallurgy tests were conducted to evaluate the presence and form of copper particles in the contact safe surface.

The MTC was able to create a route for designing, fabricating and evaluating contact safe surfaces.

A range of demonstrator components were successfully manufactured from a copper-containing stainless steel material, including door furniture and medical instruments.

The presence of functional copper particles were observed in images taken of the surfaces.

The level of S. aureus and E. coli bacteria was found to reduce by 99.8% and 98.9% respectively after 24 hours when compared to a standard solid stainless steel surface.

Contact safe surfaces offer antimicrobial benefits to industry, especially in applications which have hard-to-clean surfaces or have high microbial transmission risks.

The use of commercially available copper-containing stainless steel provides antimicrobial benefits, while maintaining the structural integrity and cost benefits of stainless steel.

By leveraging the MTC’s materials processing experts and NCAM capabilities, MTC can help industry develop and prove out the application of materials with antimicrobial properties, to provide safer work environments.