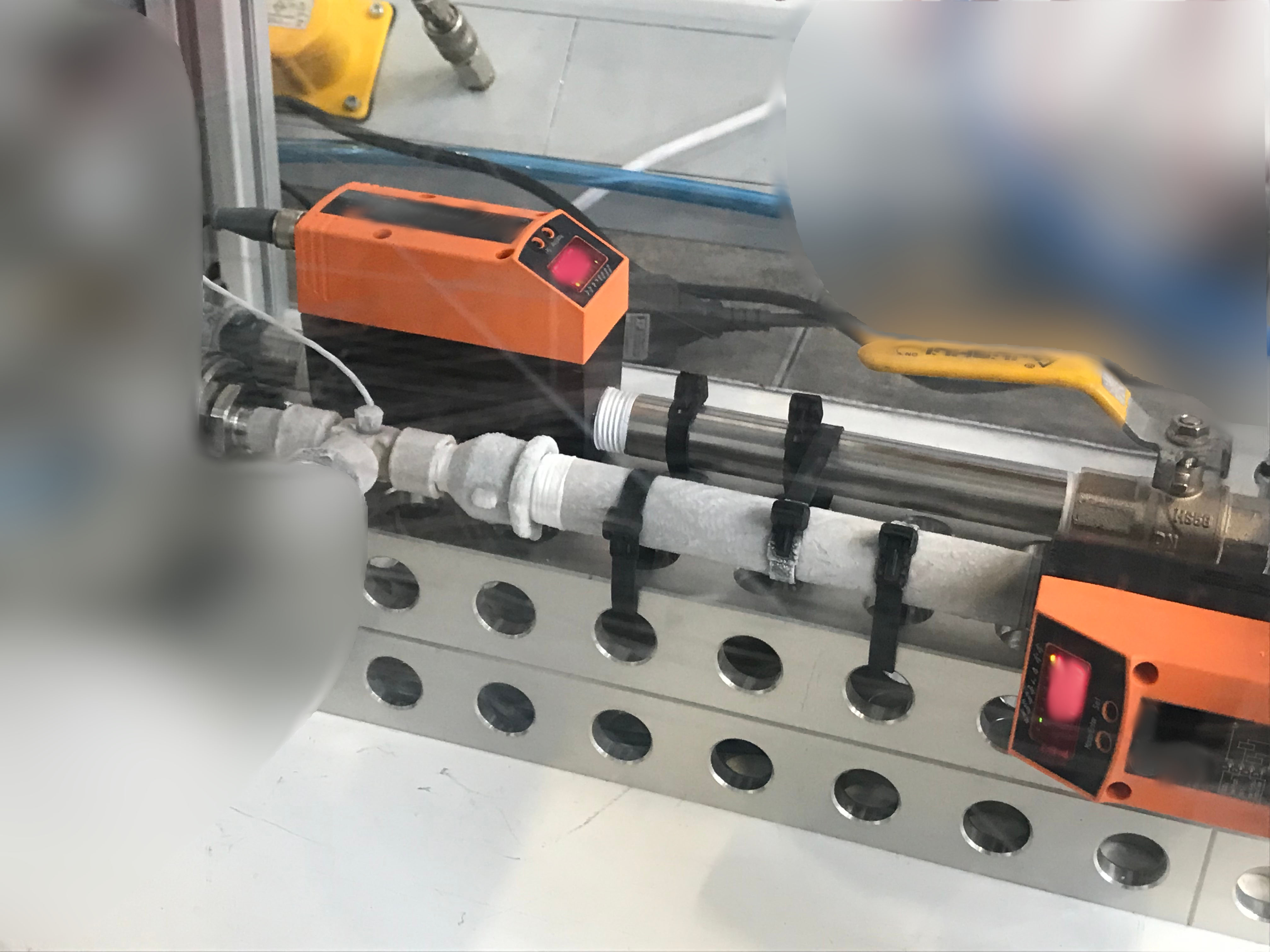

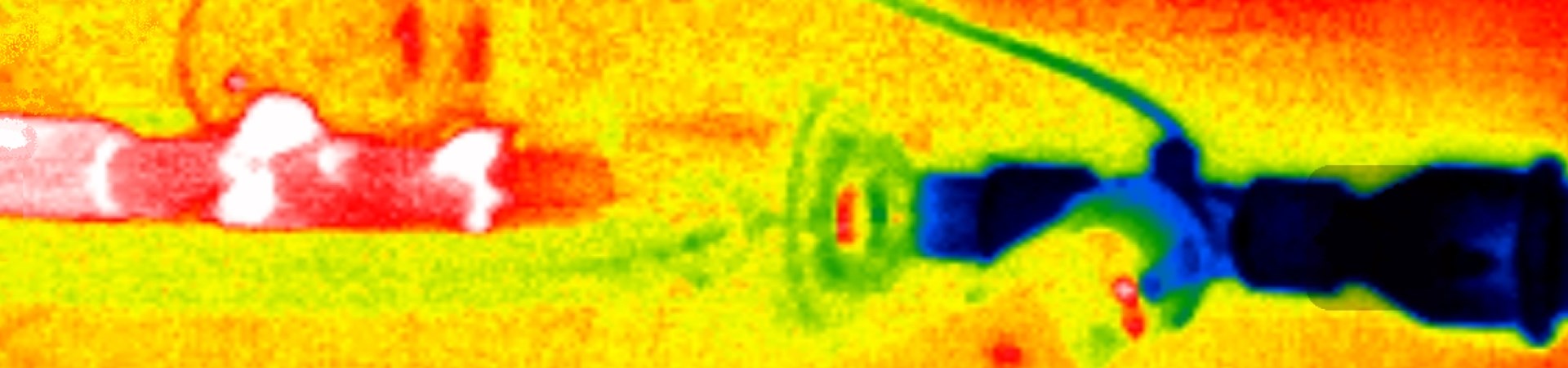

MTC was tasked by Rolls Royce to study feasibility of using alternative heat exchanging solution for potential use in their aero engines. Project comprised of in depth empirical and simulation strands that allowed extrapolation of that data to form a computational estimate of its performance with engine condition inputs. Use of the novel device could

deliver a light weight and low cost solution to cooling temperature sensitive areas of the engine.