The MTC has utilised its experience in human centred product design to produce a demonstrator that solves the problems of vaccine wastage. This product aims to increase the delivery process efficiency whilst keeping the vaccines at a constant and cool temperature.

In July 2020, the MTC completed a project that mapped out a typical pandemic timeline. It discovered many pain points that MTC could be proactive in solving. Vaccine distribution and storage was identified as the most uniquely impactful way in helping with the fight against COVID 19.

In 2018, £6.3 million of vaccines were wasted and 58% of these were due to fridge related failures. This could be something simple as the door being left open and the number was predicted to increase due to more vaccines being produced and the infrastructure staying the same.

Perform comprehensive research and design studies with multiple concepts undergoing design simulation and physical testing.

Creation of proof of principle rigs, combined with a physical demonstrator, simulating the product and process it would follow.

Creative collaboration across multiple technologies, experts and organisations.

A product that controls the temperature throughout the process, that is both safe and easy to use.

Insight into the current problems faced within the challenge, tackling the problem holistically.

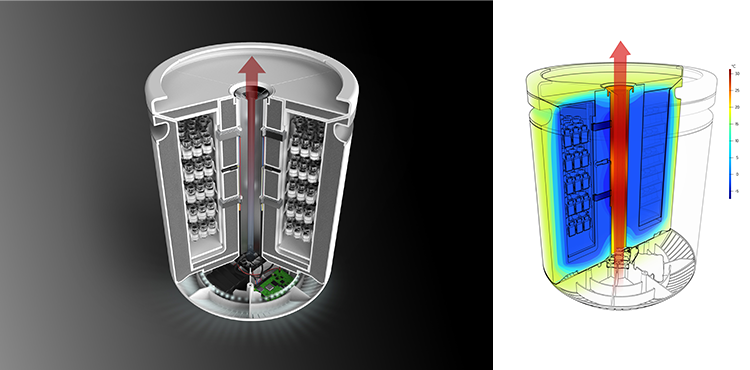

Successful design and validation of a temperature controlled vessel utilising both readily available active and passive cooling technology.

A working demonstrator unit with temperature control functionality and an intuitive lighting interface.

The vessel allows refrigerated pharma goods to be delivered safely and stay within temperature critical constraints.

Includes a digital data log for a real-time tracking and alerting of unit temperatures and locations.

The vessel contains fail safes, from a self closing lid to LED indicators to protect vaccines and maintain the correct temperature.

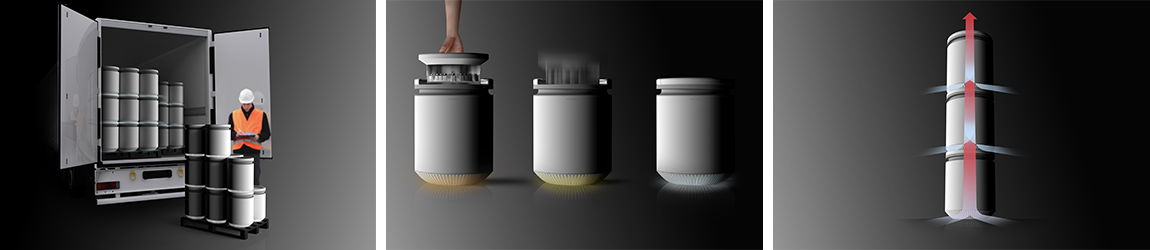

Creation of a streamlined logistic process to ensure speedy and safe vaccine delivery.

Vaccine waste is preventable and can be reduced.

Offers a scalable manufacturable solution that could aid the current pandemic, with a pallet being able to carry more than 6,500 temperature controlled vials.

The vessel has the potential to be rolled out to other medical supplies such as organs and bloods.

Design of a temperature controlled and monitored unit, proving thermal management technologies to transport temperature critical supplies.

Incorporation of a circular sustainable packaging model with the streamlined logistic process, allowing vaccines to be delivered efficiently, securely and sustainably.

The return and reuse methodology for the product reduces waste packaging and controls stock replenishment.

Imaginative engagement across different sectors, technologies and organisations.

Design thinking approach utilised to identify user needs and critical pain points then addressed with solutions.