System will enhance polymer additive manufacturing capabilities

The National Centre for Additive Manufacturing, based at the Manufacturing Technology Centre in Coventry, has boosted its polymer additive manufacturing capabilities with investment in a Carbon M2 printer powered by the Carbon Digital Light Synthesis process.

The Carbon DLS process is a resin-based system that can print a wide range of high-strength, functional end-use parts. Thanks to the Carbon M2's ability to process high performance, engineering-grade materials, these components have found applications in a wide range of industries including automotive and aerospace.

The Carbon M2 printer is enabling the MTC to improve its overall polymer printing capabilities. Recent work has resulted in the MTC becoming a certified Carbon Production Network Partner, thereby demonstrating a proven capability in producing components in a variety of Carbon 3D materials.

The MTC's Carbon DLS capability allows NCAM to offer new high performance components with high temperature resistance - up to 230 degrees centigrade. The materials available also include engineering elastomers such as elastomeric polyurethane and silicone urethane, as well as two variants of engineering rigid polyurethane.

Carbon's high temperature materials have potential in industrial applications such as heat sinks and manifolds, while elastomeric polyurethane is commonly used in automotive and consumer products, and silicone has potential in wearables.

Hoda Amel, senior research engineer at NCAM, said: "The Carbon DLS process will help enhance our polymer offerings, allowing customers a great variety of material choice and functional, aesthetic parts for their polymer additive manufacturing projects."

The National Centre for Additive Manufacturing at the MTC brings together one of the most comprehensive combinations of additive manufacturing equipment and capability in the UK. It is also home to the European Space Agency's Additive Manufacturing Benchmarking Centre.

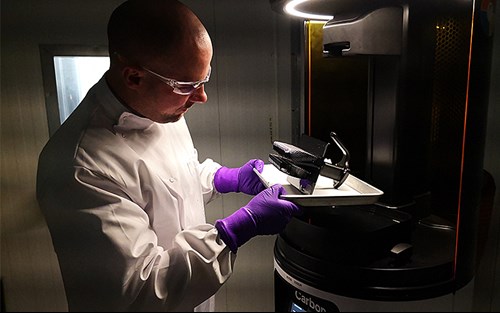

Pictured: An MTC engineer removing a Carbon certification build

About Carbon

Carbon is a 3D printing technology company helping businesses develop better products and bring them to market in less time. The Carbon DLS™ process combines versatile printers, advanced software, and best-in-class materials to deliver functional parts with end-use performance and aesthetics, helping engineers and designers to create products that outperform. From prototyping and low-volume production to production-at-scale, hundreds of global organizations, including Adidas, Ford Motor Company, and Becton, Dickinson and Company, use the Carbon process to create a wide range of functional end-use parts and print them reliably wherever and whenever they need them through our production network partners. Carbon is a venture-backed company headquartered in Redwood City, CA. To learn more, follow Carbon on Twitter, LinkedIn and Facebook.

Share this page: