In a fast-changing world, no industry sector can have the luxury of operating in isolation. To compete with the best in the world it is vital that innovations are shared across sectors. The construction industry is a case in point.

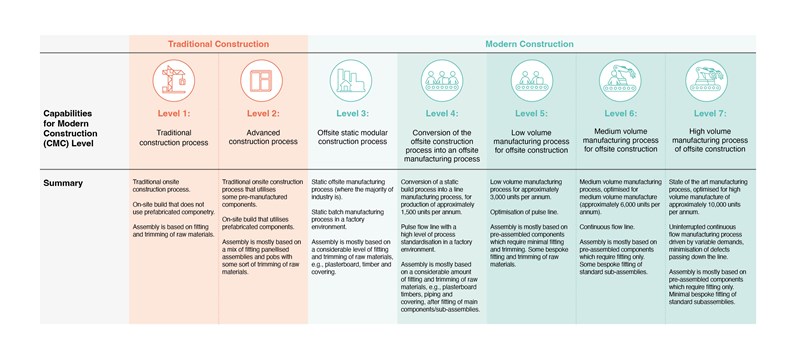

Modern methods of construction offer significant opportunities to improve operational performance, and re-engineering products and processes. As part of the Innovate UK-funded Seismic project, the MTC developed a framework to build capabilities for modern design and construction. The Capabilities for Modern Construction (CMC) matrix (Figure 1) describes in seven levels the step-by-step development of key organisational and technological capabilities required to introduce or enhance the abilities of an organisation.

Figure 1: Framework to develop Capabilities for Modern Construction (CMC)

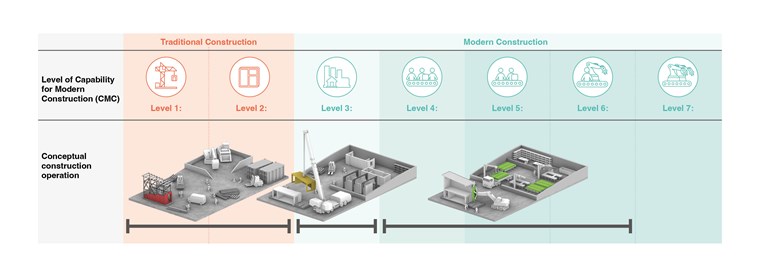

Traditional construction follows a two-step process that requires first building the structure and then completing the fit-out (See Figure 2, CMC Level 1 and 2). Modern construction methods use 2D or 3D components that include structure and fit-out; therefore, the use of such components changes the construction process into a one-step assembly process of pre-manufactured components, minimising final fitting and trimming (See Figure 2, CMC Level 3 to 7). As a result, modern methods offer significantly enhanced operational efficiency and carbon footprint reductions.

Figure 2: CMC concept diagrams. The diagrams illustrate the transition from traditional construction methods (CMC Level 1 and 2), into modern construction methods (CMC Level 3 to 7). CMC Level 3 represents a technological step change with a product (2D or 3D) that integrates structure and internal fit-out into a single building process.

Demonstrator building on display at BRE Innovation Park.

McAvoy and Algeco Group have been quick to implement technology, and as a result has seen a fourfold increase in frame production. The project data indicates that the operational efficiency doubles as changes are made.

The Seismic project has developed modern construction products and manufacturing processes. The Innovate UK-funded project consortium led by the Seismic Group includes McAvoy, the Algeco Group, Tata Steel UK, together with technology partners including the Manufacturing Technology Centre, Swansea University and the National Composite Centre.

The Seismic project showcases how the project partners used the CMC methodology to understand their product, process, design, quality and continuous improvement capabilities. In addition the project shows how the data was integrated to identify gaps and develop a programme for the development of modern construction capabilities.

Read the full case study